MARCH 31, 2020 -- A mass 3D-printing effort is underway on the UConn Health and UConn Storrs campuses to help address the shortage of personal protective equipment (PPE) for health care workers.

The result is a relatively simple and inexpensive plastic frame that creates a proper seal on the much-sought-after N95 respirator mask.

The AAUP chapters from UConn Health and Storrs brought doctors, engineers and scientists together to collaborate, all of whom already were trying individually to address the PPE shortage. In addition to the alliance of faculty unions that are part of the UConn Health Labor Coalition, the group includes graduate students (Graduate Employees Union, UAW Local 6950), UHP, and nonunion collaborators.

As Dr. Michael Baldwin (UCHC-AAUP), a UConn Health radiologist who is coordinating the production of frames and mask acquisition explains, “An example of the collaboration of our working group is the 40,000 N95 masks that were discovered in a UConn Health warehouse. Unfortunately, they were unusable because they didn’t seal properly.”

“When we shared the unusable N95 mask with our team member Chris Wiles, he showed us a retrofit frame that he'd adapted and it fit perfectly over the mask," Baldwin says. "UConn Health immediately ordered plastic to build these. Our cross-campus team will investigate the best way to keep the exoskeleton frames clean and we are also producing face shields.

“So immediately we go from a critical shortage of N95s to 40,000 potentially usable masks, and all we have to do is print these frames, which are a fraction of the cost of what buying new masks would cost."

The next challenge was printing the frames and finding enough 3D printers to do the job.

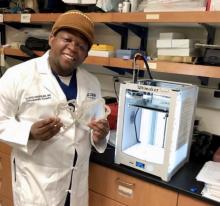

"We worked with UCH administration to inventory all of the 3D printers on both campuses," Baldwin says. "An email was sent to all of the labs requesting help. Volunteers like Elifho Obopilwe answered our call and thankfully started printing frames super early the very next morning!”

The immediate objective is to fabricate 10,000 mask frames, which can be cleaned and reused once the N95 is replaced, and individually assign them to clinical care providers.

One of the local business assisting with this effort is Wepco Plastics of Middlefield, which has offered to produce mask frames.

More than 13,000 of the N95 respirator masks that would become usable with the frames were secured by Dawn Humphries (UHP), a medical assistant in UConn Health’s Calhoun Cardiology Center. She called her friend Mike Clavette, whose family owns New England Industrial Supply in Newington, and asked if he had any PPE he could make available at cost.

Meanwhile, led by the cross-campus working group, labs in both Storrs and Farmington are busy with design and fabrication of face shields that are currently being used in the emergency department and with particle testing that could lead to the development of new masks.

“Our AAUP colleagues and other providers at UConn Health are on the front lines of caring for the public," says UConn-AAUP President Thomas Bontly. "We're proud to lend a hand and collaborate with UCHC-AAUP faculty to develop and produce much needed PPE. This is another example of how union doctors, researchers and support staff across UConn campuses collaborate on solutions to critical problems. Together we can overcome this challenge.”

Dr. Ibrahim Elali, nephrologist and president of AAUP’s UConn Health Chapter, says, “Not only are we caring for patients, but we are working with colleagues from UConn Health and UConn Storrs to problem solve for the public good. The value of our public health care center and university is proven again and again that it is the best investment a society can make for a healthier future and for the good of the public. In times of crisis, a public academic medical center such as UConn Health provides critical care to our community.”

If you would like to join the cross-campus working group, with labs in both Storrs and Farmington, please email Cindy Polinsky, executive director at UCHC-AAUP at executive.director@uchc-aaup.org.

If you have PPEs that can be donated to UConn Health, follow the link https://health.uconn.edu/coronavirus/ppe-donations/.

The UConn Health Labor Coalition consists of 4,000 union members organized at UConn Health. Representing doctors, nurses, respiratory therapists, laboratory technicians scientists, biologists, professors, dental health professionals, administrative staff, ambulance and police officers. We are currently on the front lines of the COVID-19 pandemic. The unions that represent the health care workers at UConn Health are University Healthcare Professionals (UHP), SEIU, 1199 New England, A&R, UCHP-AAUP, CEUI, and AFSCME Council 4.